Profilplast by Ramadani Cesare & C. snc has been responsible since 1977 for the customised production of equipment for extrusion of plastic material and the construction of moulds, dies, calibrators, rigid and semi-rigid PVC profiles, as well as agricultural products. Thanks to the experience gained in the sector to which it belongs, it is able to provide in a short time a customised solution and maximum precision.

Warehouse goods always under control and detailed planning of new goods orders

MES module linked to production and logistics

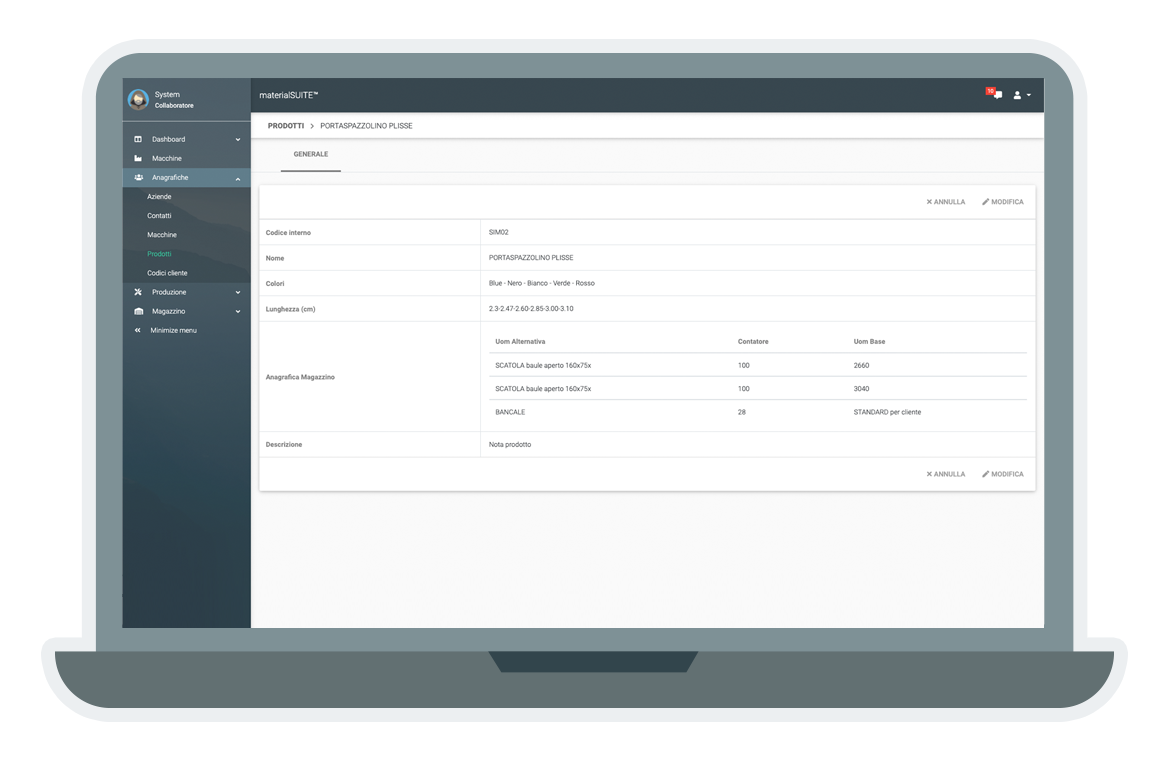

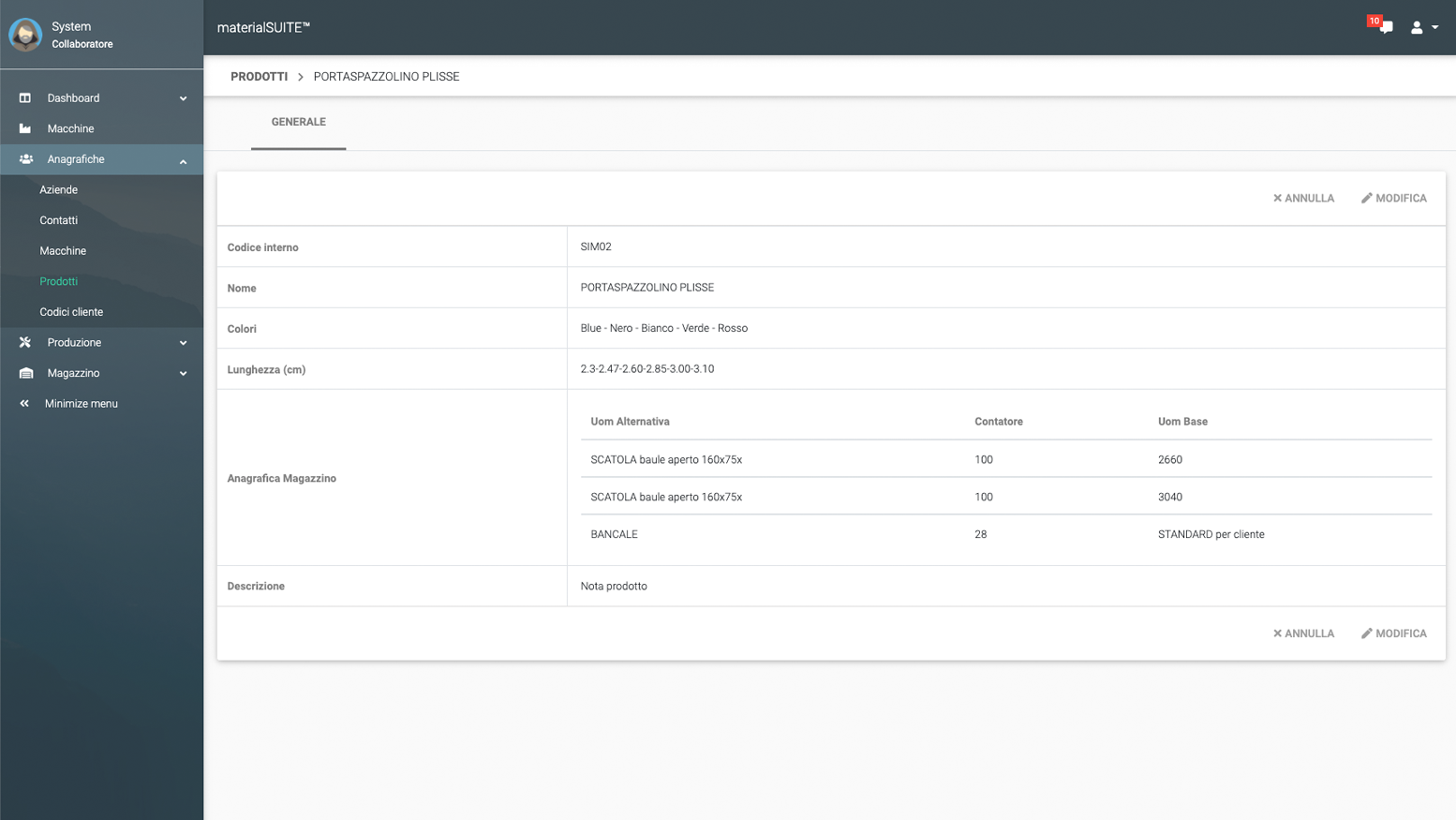

For the customer Profilplast of Ramadani Cesare & C. snc has been developed a software MES customised according to production needs. In fact, the process of production progress needed to configure the product following specific characteristics such as lengths and colors to, subsequently, send it to the production department. Through this modality the customer has the possibility to print a report containing all the orders of production, those begun and those concluded creating a flow communicative with the warehouse of the own factory. The logistic department through this software will have the possibility to manage in more efficient way the business resources inserting like “reserved” and “used” the relative goods of warehouse. Moreover in base to the enlivenments of warehouse it is possible to carry out in agility the inventory of warehouse, to proceed to the loading of new material to warehouse and to know in advance the moment in which it is previewed its arrival near the company.

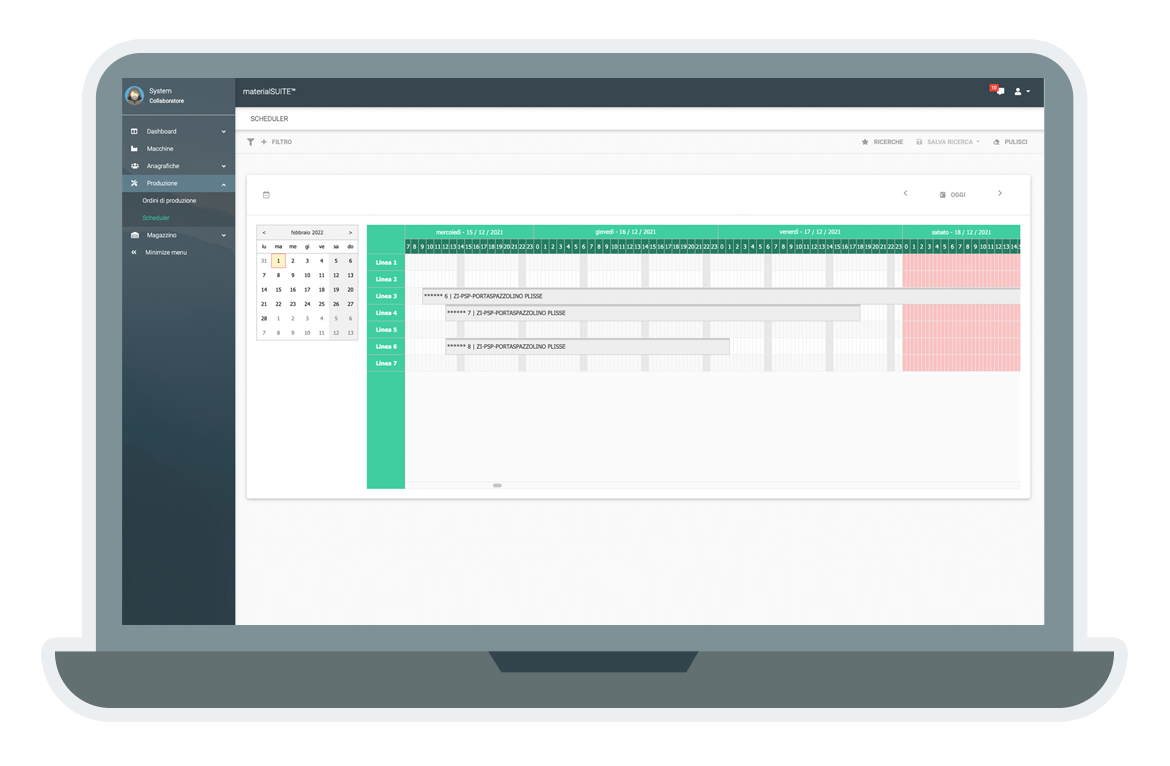

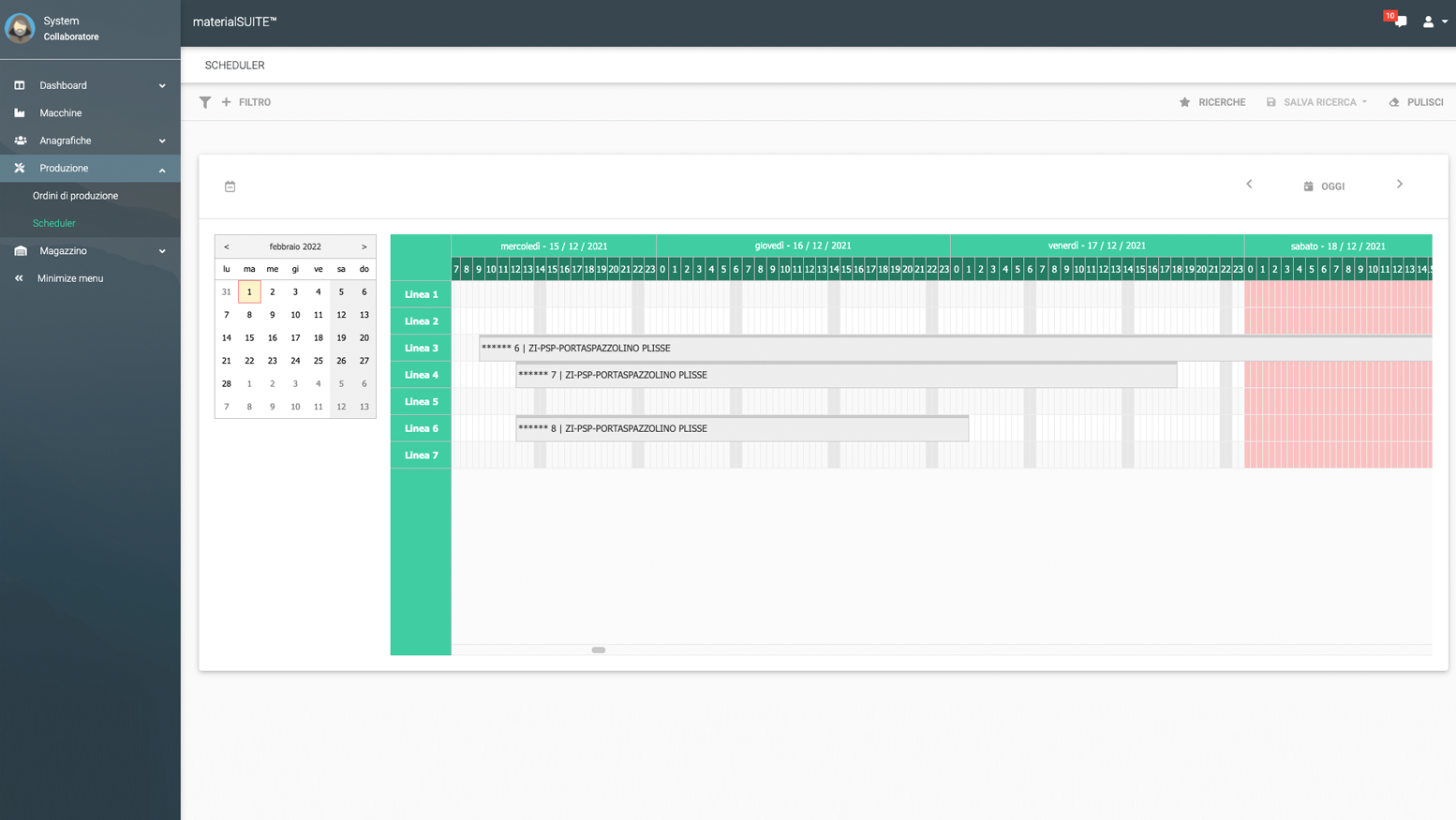

The MES contains a total of 7 machines for monitoring production and collecting information.

The project is completed by the addition of the SCH module, a software scheduler for the agile management of BOM production lines thanks to the ease of use and the excellent user experience of the graphical interfaces.

Objectives

Optimise the management of your production and logistics system, knowing the status of goods in stock, production and processed products.

Solutions

Software for 4.0 MES able to optimise the production progress and know the availability of goods in stock, planning orders and orders accordingly.

Benefits

Printing operation of labels to be affixed to the pallets the next printing of the production order orders to be made. Warehouse goods always under control and detailed planning of new goods orders. The software allows to know the exact quantity of pieces to be produced, in production and actually produced. In addition, the machine’s insights also show the status of the machine by highlighting alerts and overheating.

Integrations